|

|

Model:PL/PW100T汽油液压泵

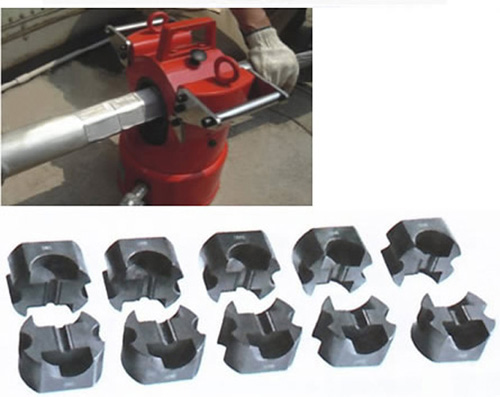

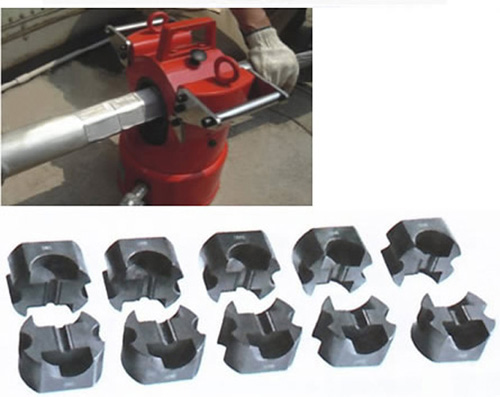

A brief account : PL / PW -type high pressure gasoline pump is my company designed a new generation of products , it is by gasoline engines, high pressure pumps , tanks and other components. Power unit allocation of domestic first-class power gasoline engine, its features are: small size , compact structure , light weight , high pressure, flow, lifting pressure fast , smooth , etc., especially suitable equipped with large tonnage crimping machine , jack, punching machines and other work , high production efficiency . Now widely used in electric power , mining, petroleum, railway and other industries , won favorite. The company's products implement three policies , guarantee period of six months.

Second, the technical parameters : 1. High pressure : 0MPa ~ 100 MPa, high pressure flow : 0.8L/min. (2) Low pressure : 10 Mpa, Low flow : 6L/min. 3 Power : 4.5KW. 4 Dimensions: ( L × W × H ) 650 * 550 * 500.5 Weight : 58Kg

Third, use: gasoline engine should be checked before use and oil tank . Use the manual unloading valve handle in position and pump connector and the appliance is equipped with hydraulic connection connected, then press Start to start gasoline engine gasoline engine , to be run for 1-2 minutes . The manual valve handle in booster position, then the hydraulic oil pump output begin to work. End of the work , the manual valve lever to the unloading position , close the throttle until the end of the hydraulic oil back to the oil , remove the connector. ( Note: The two-way valve for manual output about the same, just in a different direction , please note that select the interface , unloading position in the middle )

Fourth, the use Note: 1 , pump with 32 # 10 # hydraulic oil or machine oil . 2 , fuel storage must be on top of the oil window range ( try not to exceed the oil window ) . 3, each fuel and oil change, oil filter must be used more than 80 mesh mesh filter , change the oil when the need to clean the tank. ( Oil change period of 6 months ) . 4, the working oil temperature 5 ℃ ~ 50 ℃. 5 , will be required before starting pump hydraulic valve handle in the unloading position . ( Note : One-way D- , bi-directional median ) . 6 , before adjusting the pump out of the company , are not free to increase the pressure . Need to re- adjustment shall not exceed the maximum pressure specified in the instructions to avoid damage . 7, due to aging of the hose is easy to check the technical parameters specified when the pressure is at 1.4 times the pressure test and, if blasting , raised, leakage and other phenomena must not continue to use. 8 , bearings generally six months cleaned once a grease fitting is required . 9 , the use of gasoline in strict accordance with the instructions ( see assembly instructions momentum ) .

V. Common Faults and exclusion method : |

|

Fault |

Generating reasons |

Exclusion method |

|

Insufficient pressure or no pressure |

1、Valve adjustment is too low, or cone valve stuck

2、Unloading valve orifice wear or damage steel

3、Connector is loose or damaged seals

4、Pressure gauges, pressure damping response distortion caused by clogged |

1、Adjust or repair clamp valve or valve seat

2、Ball valve replacement or repair

3、Replace the seals, fastening fittings

4、Check the pressure gauge or experience Gauge Block |

|

High flow shortage |

1、Plunger or plunger spring break gap wear

2、Oil temperature is too low suction difficulties, the oil temperature is too high volumetric efficiency decreases

3、Level is too low, the pump suction air |

1、Replace plunger or piston kits and other pieces of other

2、Control oil temperature between 25 ℃ -50 ℃

3、Add enough oil |

|

| |

|

|

|